Colours

When it comes to Architectural Concrete, No one knows it better than Nauhria...

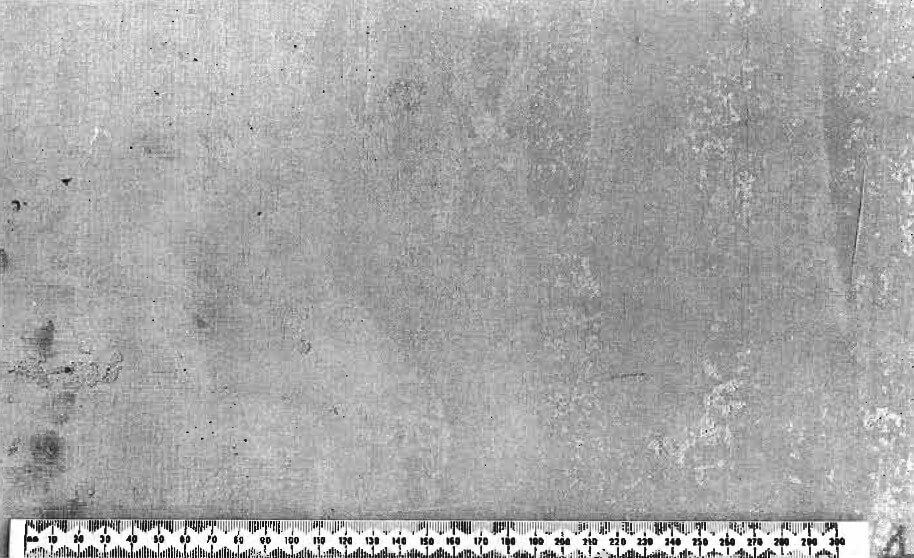

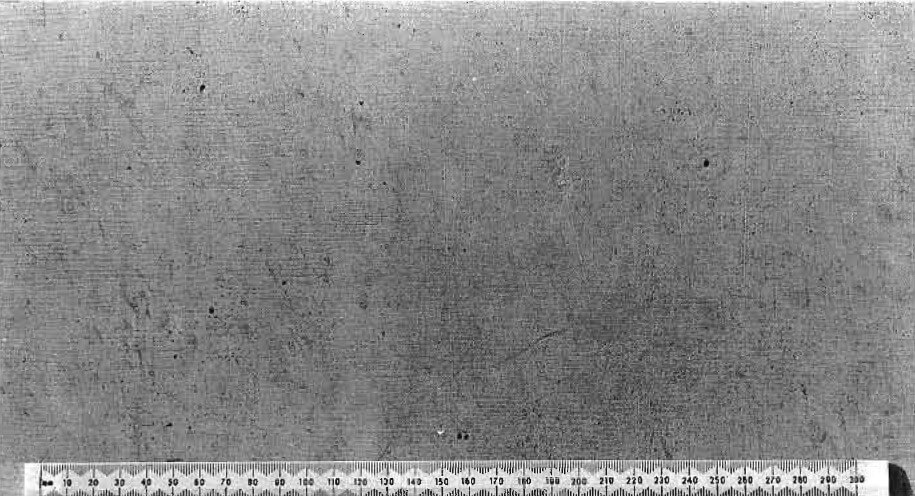

Natural Concrete

Natural Concrete is typically coloured Portland Grey , the resulting formulation of Grey cement, sands and aggregates being mixed together.

White Concrete can also be made substituting the Grey cement for White cement where Carbon has been reduced from the cement.

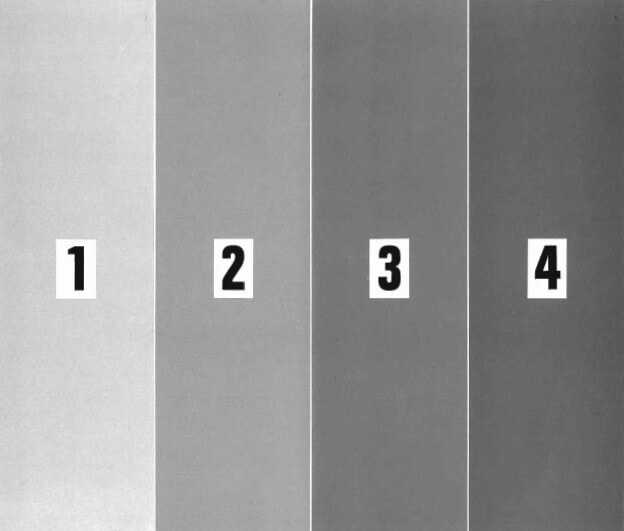

Oxide Colours

Enhancing concrete colours to achieve pre-coloured concrete requires the addition of coloured Oxide powder to the concrete formulation.

Oxides come in a range of standard base tones including: Black, Brown, Terracotta - Red, White - titanium dioxide, Green, Yellow and Blue.

Most oxide distributors like Peter Fell Ltd offer formulated preblend colours to provide a unique colour offering more in keeping with modern decor trends and the subtle accentations of space.

To see a full range of oxide standard colours we recommend viewing the Peter Fell website.

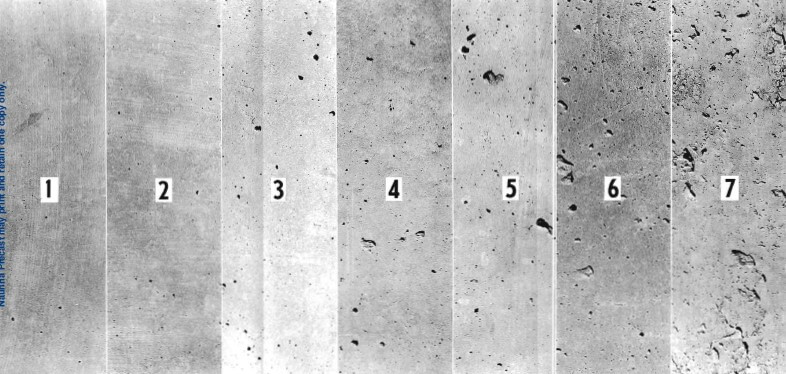

Oxide Dosing

Achieving a consistency of colour managed by dosing common percentages of oxide by the cement content of the concrete.

Typically most oxides are dosed at 5% EG. if there is 400 kg of cement per /m3 5% would require 20kg of oxide powder to be added per m3.

Offset Shades of colours can be achieved by lessening or increasing the oxide dosage to a maximum saturation level of what is typically considered to be achieved at 10%

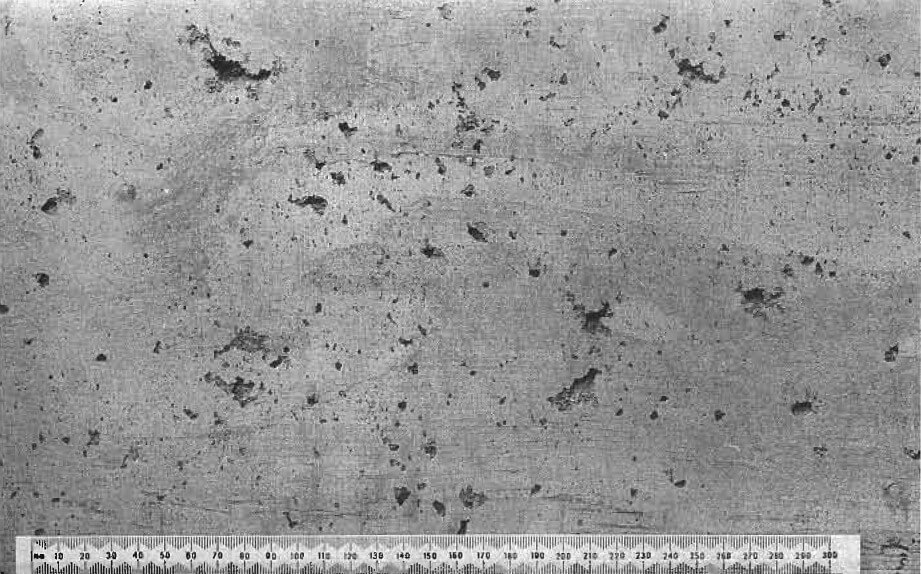

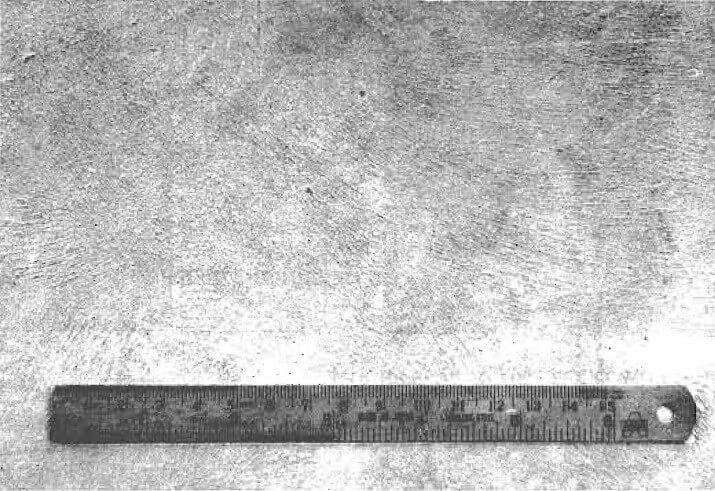

Colour variations

Whilst Nauhria take all practical precautions to manage colour consistency as close as is practically possible It is important to be aware that environmental factors outside of their control can also effect the colour of concrete whether colour enhanced or natural. This includes Humidity, Sun, Wind, Raw ingredient moisture content and naturally occurring contaminants like dust and other source debris.

Coatings can also cause a significant variation in colour tone ranging from Acrylic Silane siloxane based coatings that will render a natural dry colour to Solvent based penetrating coatings that will provide a deep dark and lustrous wet look appearance. combinations of contrasting coatings are commonly used for Dynamic decorative effects providing perfect colour harmony and an offset of colour tone.

The Base ingredients of the concrete formula can also effect the concrete colour with cleaner sands aggregates and white cement resulting in more dynamic vibrant colour enhancements.

Costs

As base oxides are made from naturally occuring - colour fast materials, So do the costs associated with their abundance impact the cost accordingly. In New zealand our most cost effective colour is Black, made from carbon and Iron ferrox. While colours like White -Titanium Dioxide and Greens and Blue - Cobalt typically at the higher price range of colours.

Colour Permanence

Dosed and blended in with the cement, Oxides are entrained throughout the concrete matrix for the life of the concrete.

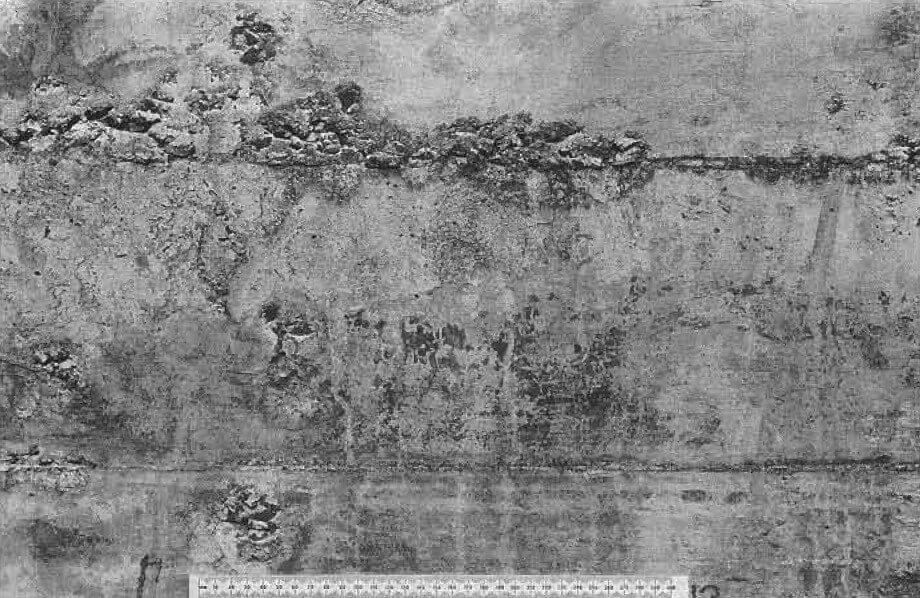

Oxides - being made of powdered colour fast solid matter rather than pigmented dyes cannot fade over time however salts within the concrete can be brought up to the concrete surface wet dry action on the panel of which water evaporates leaving the white salt on the surface atop the oxide giving the appearance of a gracefully aged faded colour. This is known as efflorescence and is a common phenomenon found in concrete and concrete blocks. It can also be easily removed and washed away by professional cleaners with chemical treatment.

Prevention of efflorescence is best achieved by preventing the transfer of moisture into and out from the concrete through water proofing or repelling coatings and admixtures

As Colours are locked in for the life of the concrete it is important to consider also changes to the use of the building over long periods of time, Changes in Decor, Changes in tenancies, or just evolution of personal preferences. Keeping with neutral tones will help to compliment and change of decor, colour or aesthetics, brands or furnishings which more easily changed. Colours like black, White, Greys and earthen tones tend to be best for complimentary longevity of colour.

Concrete Stains

Modern concrete treatments also include colour fast concrete stains that are specialist applied to the surface of the concrete. Concrete stains offer an excellent life of aprox 20 years before requiring any degree of recoating. Colours can also be matched to blend concrete imperfections or to make good concrete repairs and remedials.

Exposed Concrete colours

During some Concrete exposure techniques like Monarc's Diamond Honing, Bush Hammering or Diamond brushing, Natural aggregate colours become visible revealling the beauty of the polished surface itself. this revealling can make visible variable aggregate properties include veins of quartz and other minerals, fossils, and simple variatons of natural colour occuring with chemical compositions of the aggregate.

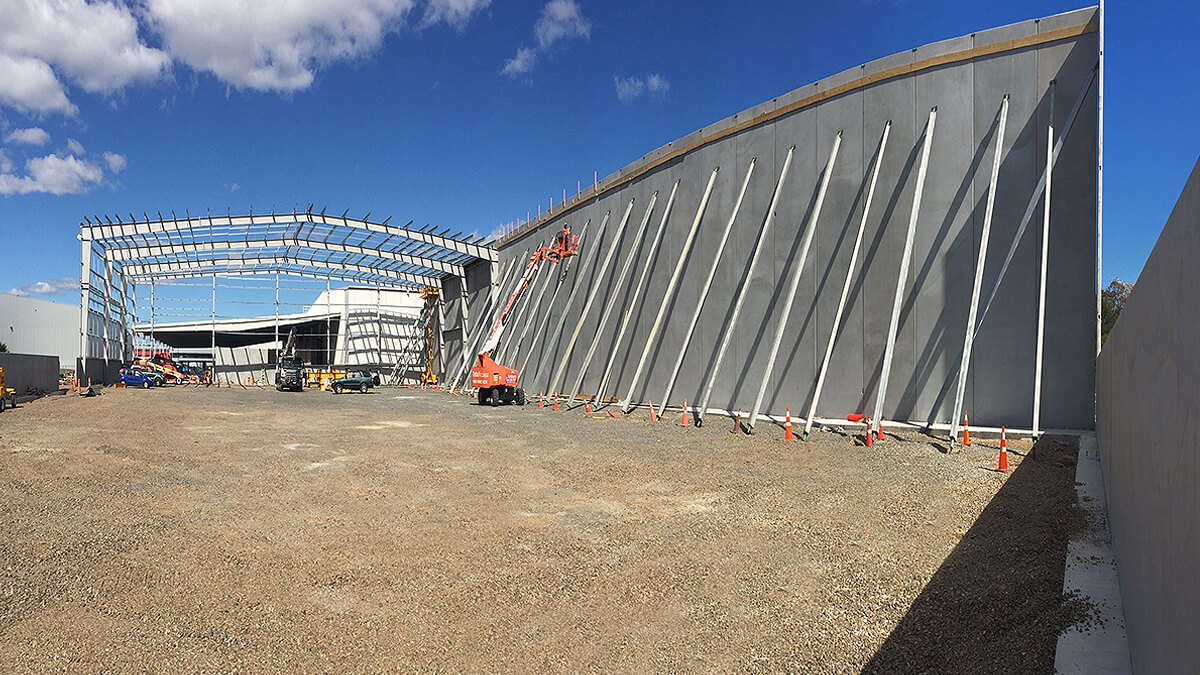

Play of Light

Natural Light is made up of all colours bouncing off surface to reflect certain frequencies of light and to absorb others, To our eye the reflecting light frequencies are interpreted to what we refer as colour. Keep in mind the light frequencies bouncing first off other items like green from trees, The blue of the sky or the high vis vest your wearing when you view a sample, commonly impacting on the true colour we see.

As light changes colours so does the appearance of Darkness and Shadow - Through the movement of the Earth around the sun and the changing angles of light through the day, variabilities of colour and tone is commonly experienced.