Pre-cut ' n ' Bent

Pre-cut ‘ n ‘ Bent

Precut ‘ n ‘ bent reinforcing steel product from Nauhria Reinforcing, delivers accuracy and continuity of custom formed rebar components making insitu on-site steel fixing faster, easier and highly efficient.

Avoid the waste and cost of scrap offcuts, Free up valuable labour hours by letting Nauhria’s technology provide accurate measure, bend, radius and cutting of rebar to meet your projects exacting requirements, and have confidence that product from Nauhria is fully conforming to the exacting requirements of New Zealands Standards and Codes.

Steel Fixing

Steel Fixing

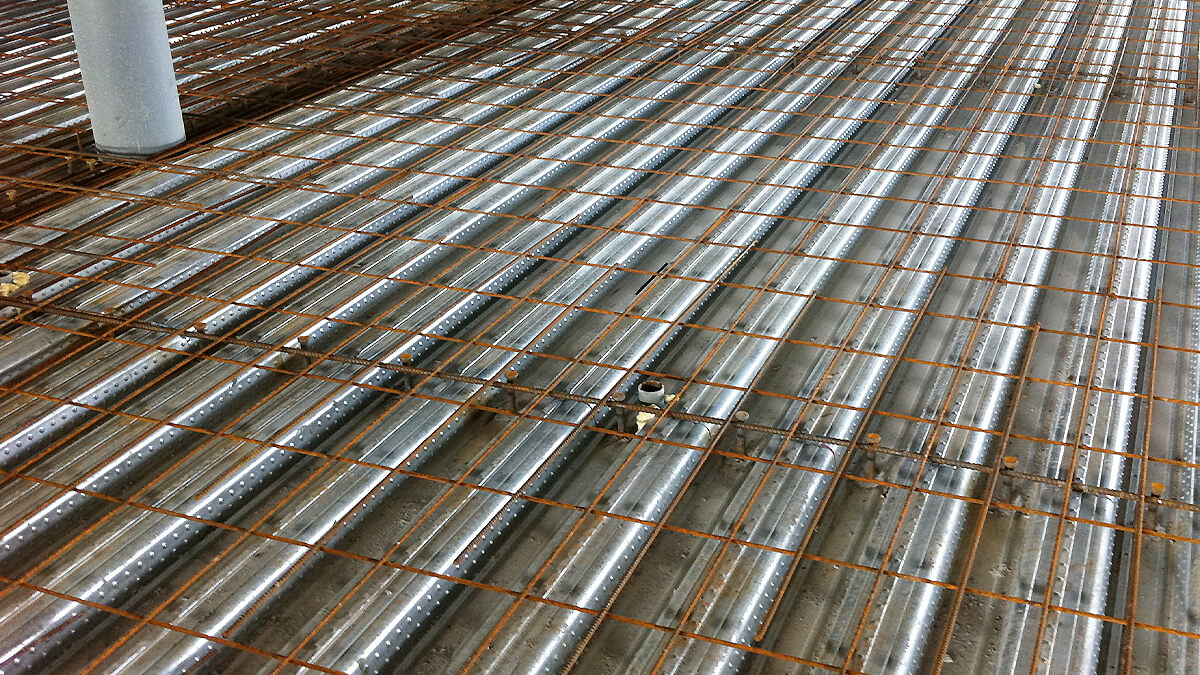

Steel fixing insitu on-site requires an experienced understanding of best industry practice coupled with a little bit of muscle.

Forming footing cages and placing them accurately within in-ground trenches, seamlessly stitching them together while establishing set surface coverage – ready for inspections and concrete pour requires experienced planning, coordination and effective communication with the site manager and other trades to ensure the concrete pours ontime and most importantly that the engineered design performs as intended.

Concrete slabs, Insitu concrete columns and walls etc often require special treatments, Nauhria’s steel fixing teams are highly experienced and arrive onsite prepared and ready to complete the work at hand.

Detailing

Rebar Detailing

Nauhria’s experienced Rebar detailers interprets the project engineers design from the structural drawings supplied and in accordance with industry best practice and in compliance with the New Zealand’s building standards and codes, then prepares schedules of custom rebar components ready for fabrication and bundled hiab delivery to the project.

Having clear drawing information and a clear understanding of the project programme is paramount to ensuring the right product is made and delivered to site at the right time.

Nauhria’s detailers have extensive experience on all magnitudes of projects and often provide solutions to errors or omissions with a proactive approach together in collboration with the project engineers, the effect often saves both time and money to the build.

ASA

Nauhria use ASA software to ensure traceability of project progression, manufacturing and delivery of goods to the project, Tear proof traceable tags match to delivery schedules for onsite delivery checking and proof of delivery.

Fabrication

Fabrication

Nauhria Reinforcing’s production factories operate 24/7 where fabrication of custom rebar components is carefully planned for efficient ganged production.

Nauhria’s Automated MEP Numerical bending technology processes upto 16mm dia bars, Round or deformed, from stock lengths to ensure post-bend bar strength is achieved.

Larger Diameter bars (20 – 32mm+) and X,Y,Z dimensional bars require manual processing with electric shears and benders.

Minimum Bend Radiuses are maintained at all times in accordance with the NZ Standard.

Components are bundled together and tagged ready for scheduled Hiab delivery to site.