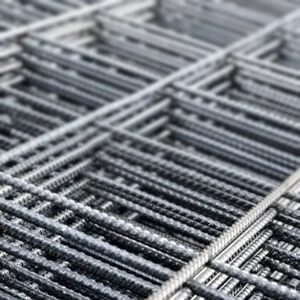

Ductile Mesh

Designed to meet The Department of Building & Housing (DBH) new B1 Compliance standard.

Manufactured from locally produced ductile wire.

Sheets individually tagged and Test certificates available.

Tested to ensure compliance to AS/NZS 4671 Ductility 500E standards.

300mm Bar spacing for easy “Step Through” while placing and working on site, using the 73 plus range.

Easy lapping with Double Edge Configuration, using the SE73DE, 72, 82 and 92 PLUS range.

Designed with Ductility to Minimum 10%

Minimum Yield strength 500 MPA

| SE62S |

4450 x 2020mm |

6.1mm |

21.2kg |

200mm centres |

7.560m2 |

| SE62 |

5050 x 2020mm |

6.1mm |

24.7kg |

200mm centres |

8.640m2 |

| SE62L |

6050 x 2420mm |

6.1mm |

35.25kg |

200mm centres |

12.760m2 |

| SE73DE |

5000 x 2270mm |

7.5mm |

29.1kg |

300mm centres |

10.080m2 |

| SE73LDE |

7100 x 2270mm |

7.5mm |

40.6kg |

300mm centres |

14.490m2 |

| SE72DE PLUS |

6400 x 2370mm |

7mm |

48.5kg |

200mm centres |

13.640m2 |

| SE93DE PLUS |

6800 x 2270mm |

9mm |

54.9kg |

300mm centres |

13.860m2 |

| SE82DE PLUS |

6400 x 2370mm |

8mm |

61.8kg |

200mm centres |

13.640m2 |

| SE92DE PLUS |

6400 x 2370mm |

9mm |

78.1kg |

200mm centres |

13.640m2 |

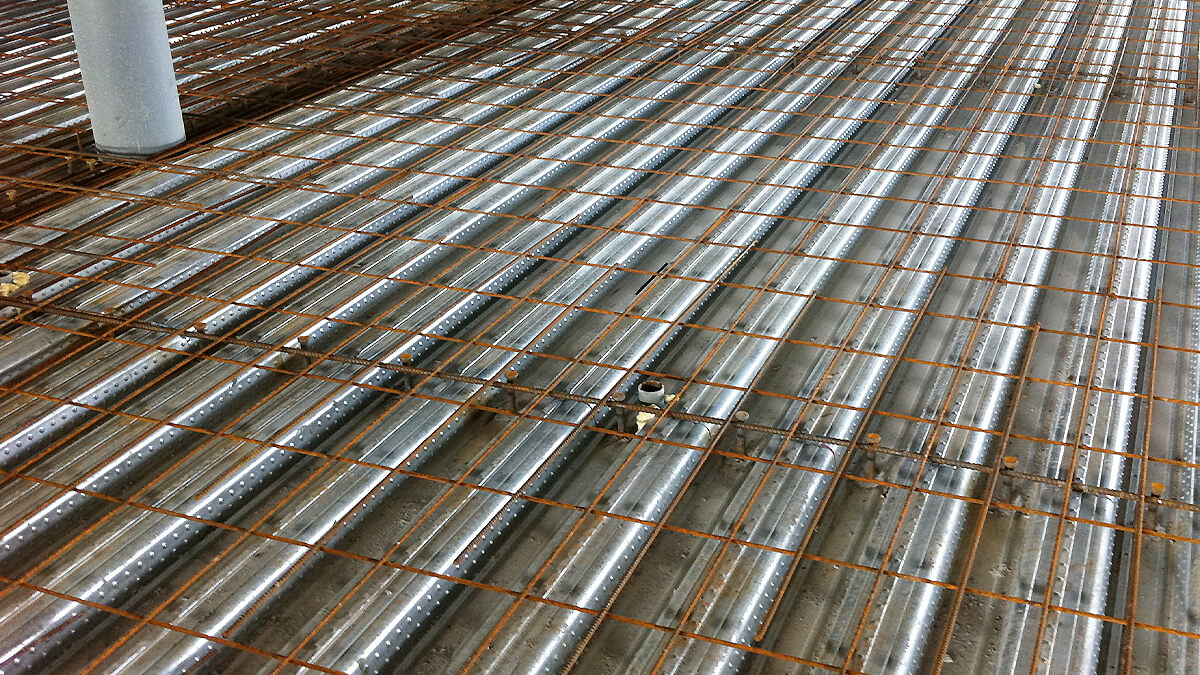

Mesh Placing Guide

Overlapping Mesh

Mesh should be placed with a minium 1 bar overlap or as specified in product guidleines.

Double edge mesh requries less overlap area but requires 2 perimeter bars to overlap sheet edges.

Mesh Storage

Mesh should be stored flat and covered from rain. Ideally it should be placed on dunnage to keep it clear of ground water to prevent corrosion.

In geothermal areas of New Zealand Mesh is best stored internally to avoid accelerated corrosion caused by environmental factors.

Bar Chairs / Spacer Bars

Positioning of mesh midway between the Top and bottom surface of concrete to be poured is critical to help protect the steel bar from moisture penetratiuon and corrosion.

Plastic or concrete spacers are commonly used and should be attached to mesh at a minimum 1.0 m2 spacing. Mesh should be positioned mid space to ensure clearance of Post pour cuts and to maintain adequate cover protection both from surface water and from ground moisture.

It is common practice for Polythene sheeting to be laid down prior to base course and and concrete to prevent moisture transfer from the adjacent earth.

Health and Safety

When Cutting & Triming mesh beware of hot sparks and shards, Sharp metal projections and potential for tripping.

If using grinders ensure full PPE is worn and ensure guards are fully in place on tested and approved equipment only.

Where possible workers should avoid standing on top of mesh as this can may deform the mesh sheet and due to its instability can become a significant trip hazard.