Concrete Panels

Related Projects

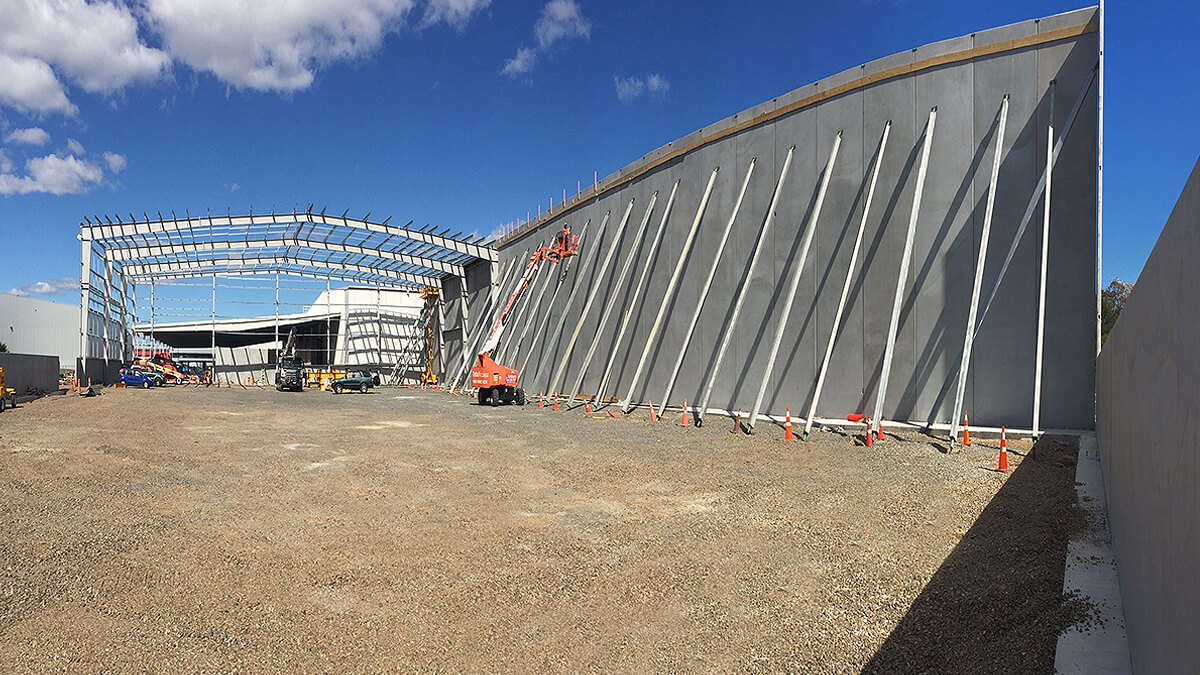

Traditional Precast Wall Panels

Precast Concrete Wall Panels are designed as a structural building elements in many of today’s modern buildings. Pre-manufactured offsite, Nauhria‘s precast panels are made in advance and stored ready for agreed delivery dates to exacting dimensions and specifications.

Panel Dimensions

Achieving cost efficiency of precast is often a balance of unit dimensions / volumes with setup, manufacturing, delivery and installation costs.

Small panel areas may appear high in m2 rate, this is due to fixed unit costs amortised over a smaller panel area, on the flip side, Large oversize panel areas can required specialised transport, pilot vehicles, permits and heavier craneage for lifting and installation. Nauhria can work with you to achieve efficient precast design and planning.

While panels may be cast from +/- 75mm in thickness, Panel Width and Height should be considered against risk of breakage with the processes and handling that a panel will go through from casting to handling transport and erection.

Slender width panels or panels with openings may also require an increased panel thickness to prevent bowing and risk of panel cracking.

Rough Guidelines For Panel Size to Thickness:

| W x H | Min Thickness |

| 1.0 x 2.0m | 75mm |

| 1.5 x 4.0m | 100mm |

| 2.0 x 6.0m | 125mm |

| 2.0 x 8.0m | 150mm |

| 2.0 x 10m | 175mm |

| 2.0 x 12.0m | 195mm |

| 2.0 x 14.5m | 200mm+ |

Professional Engineers will often collaborate with Naurhia to aquire a thorough understanding of precast constructability constraints and will incorporate this into their designs. eningeering constructability upfront in the project can provide significant savings to a project.

For cost savings and efficiency Nauhria utilise a range of reuseable extruded formwork systems

Standard formwork thicknesses including 120, 125,130, 150, 155, 165, 175, 180, 200mm ( incorporates typical top and bottom 15mm chamfers)

Custom height formwork dimensions can also be created integrating with extrusion chamfer capping to top and bottom edges.

Panel edges requiring Stitch joint details, special profile, Starters bars, Hairpins or other cast in componentry may often require single use or destructible formwork.

Click for Precast TechnicalBenefits of Precasting

Time Savings:

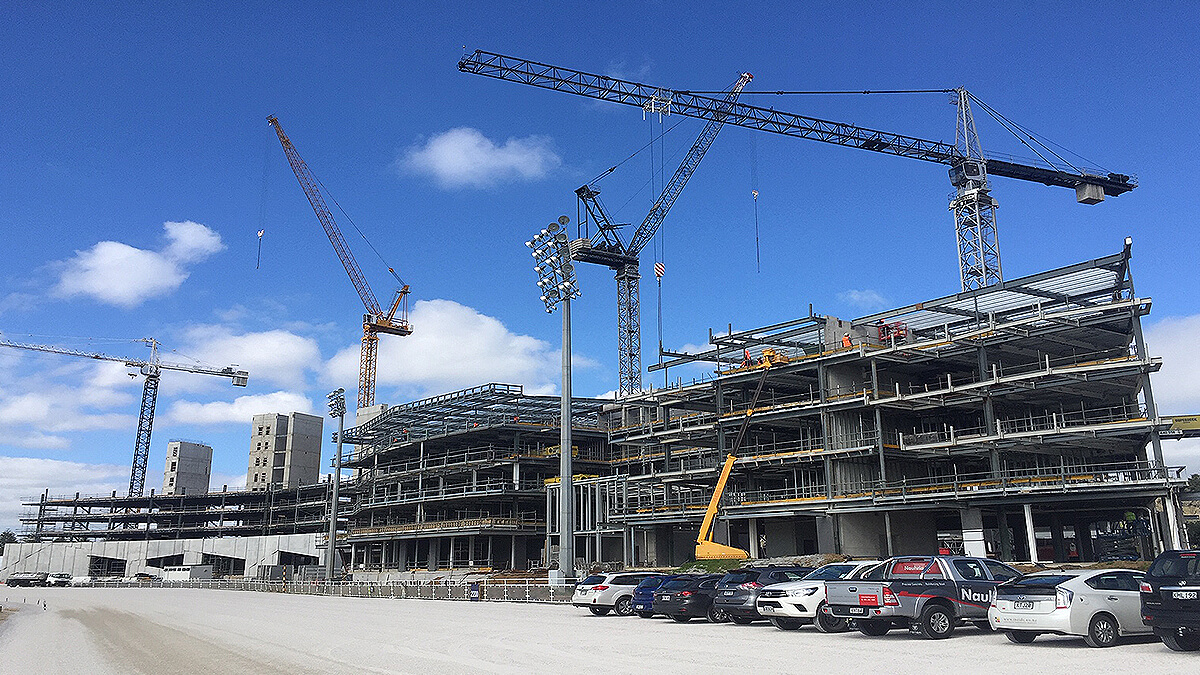

While site works are progressing precast panels can go through multiple processes including drafting , precheck and approval of shop drawings. Once approved by the project engineers, Panels are then manufactured and stored ready for the date of delivery where multiple panels can be delivered together. this significantly reduces craneage and installation time and costs onsite.

Space Savings:

Precast Panels are manufactured and stored off-site in safe engineered panel racks designed to hold the loads of multiple panels of substantial weight and size. This eliminates the need for onsite casting and storage freeing up space onsite to allow continuity of other trades and clearance for site movements and structure.

Financial Savings:

Precasting concrete units with Nauhria is very efficient. Their internal casting and storage facilities are fully equiped with Gantry cranes allowing instant movements of panels, Dedicated heated casting beds allow for accelerated curing with controlled gradual temperature rise that both reduces casting time and increasing product aesthetic quality and uniformity. casting equiptment and stores are readily available improving fabrication efficiency and allowing immediate casting post shop drawing approval. Common elements can provide economies through mould and jig creation and bulk purchasing of common materials such as lifters inserts and release agents. At Nauhria these savings help us to remain highly competitive while maintaining the highest standards in product quality.

Better Product Quality:

It is often the small things that make a significant difference, Nauhria utilise Supermagnetst to hold formwork to Steel tables protecting tables and eliminating th eneed to ramset nail through steel plate to secure the boxing, this protects the tables resulting in better panel surfaces. Naurhia’s heated tables provide curing with controlled heat being evenly distributed across the full surface area of panels this provides a better appearance to the panels with curing uniformity and signifcantly reduces centralised hydration zones commonly experienced with non-heated casting. Heating also provides a higher pre-lift strength of the concrete reducing the risk of chips and remedial works being required.

- Precast Panels provide many benefits including longevity, strength and durability.

- Concrete panels provide excellent properties for fire and acoustic insulation and can be design to 100+ year design life.

- They can be used for retaining earth or tanking liquid, bridging or signage,

- Concrete still remains today from historical concrete formed 1000’s of years ago…