Precast Panels come in a variety of custom sizes and shapes.

For lifting, storage, Monarc processing and transport to site, Monarc panels are generally managed with the long edge down. Panels are then rotated onsite mid-air during the cranage and installation lift.

With Monarc’s unique ability to offer many different finishes, each tooling refinement process has a limited dimension, Panels must be designed or split to fall within these absolute maximum dimensions:

MAXIMUM MONARC PROCESSING DIMENSIONS:

Minimum Unit Thickness: 100mm

Maximum Unit Thickness: 500mm

Maximum Unit Weight: 18 tonne

Maximum Standard Delivery Length of Unit: 12.0 meters

(Larger units may incur specialised transport costs. (See Transport Specs.)

Maximum Panel Processing Height (from panel long edge) :

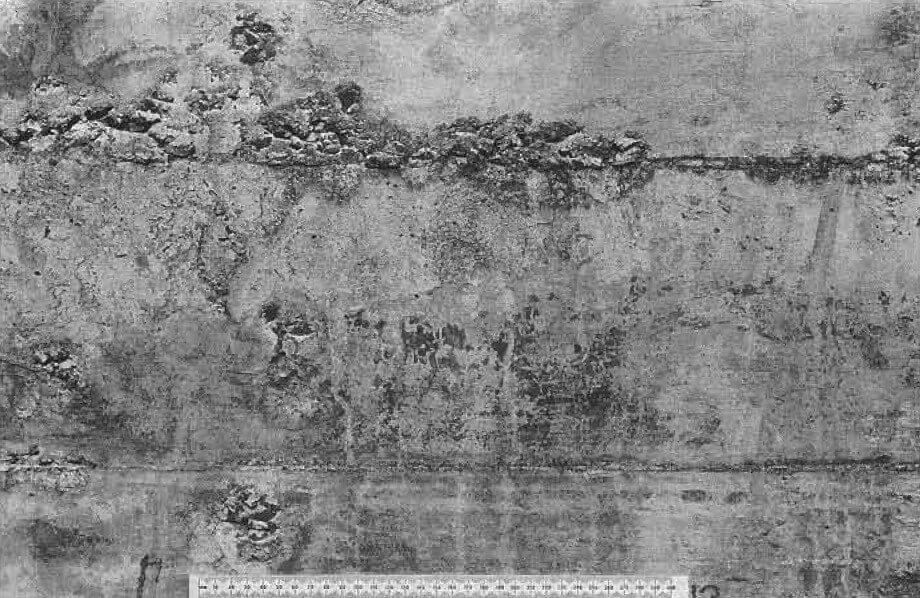

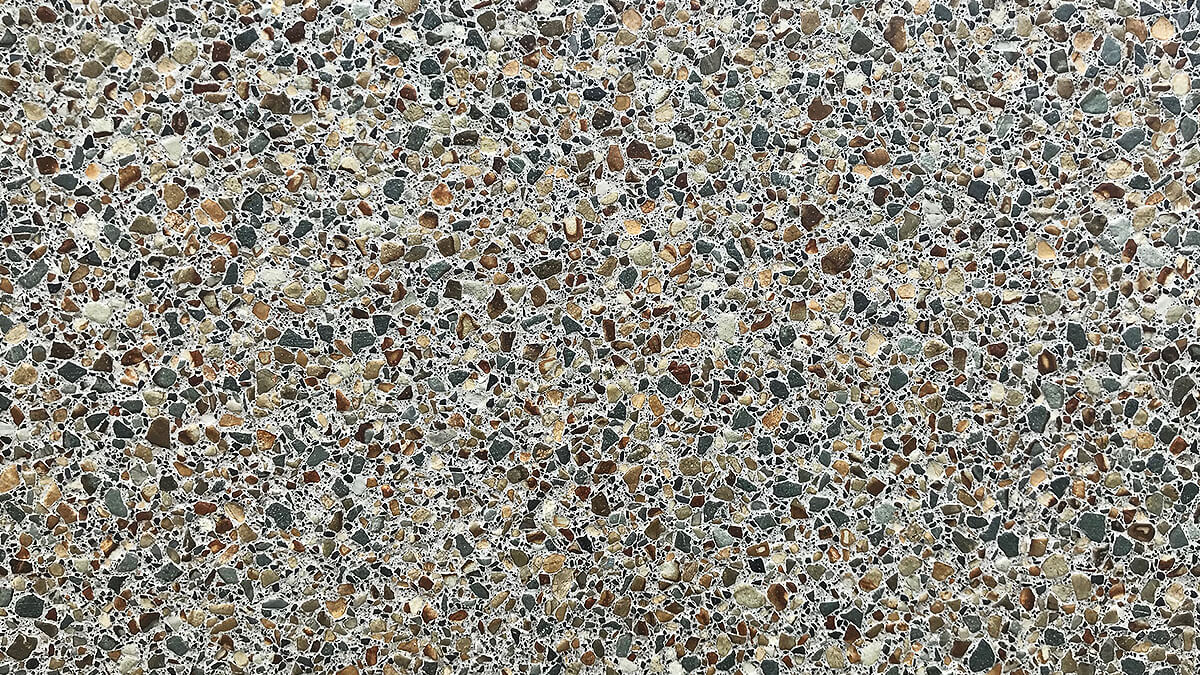

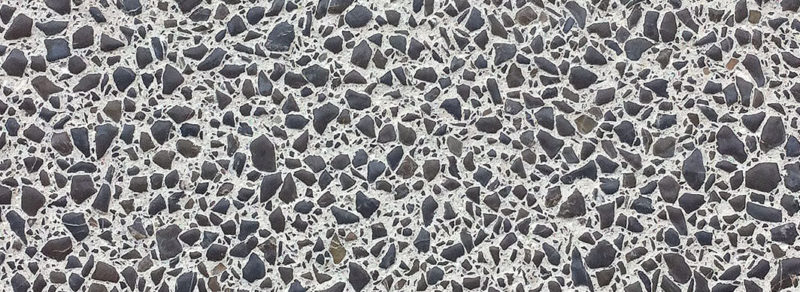

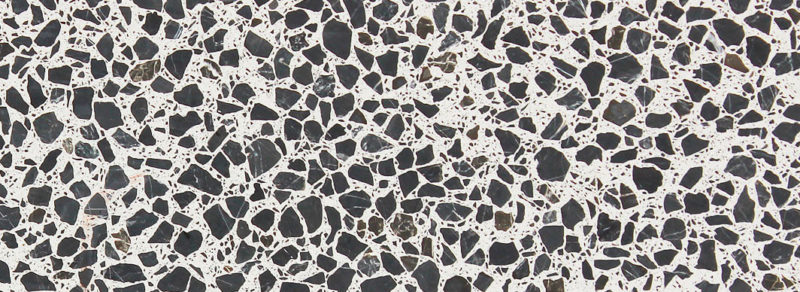

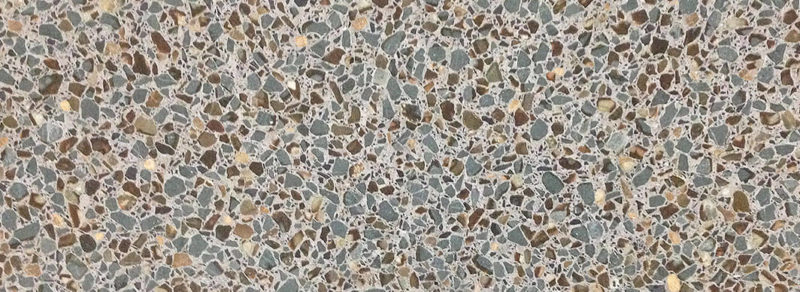

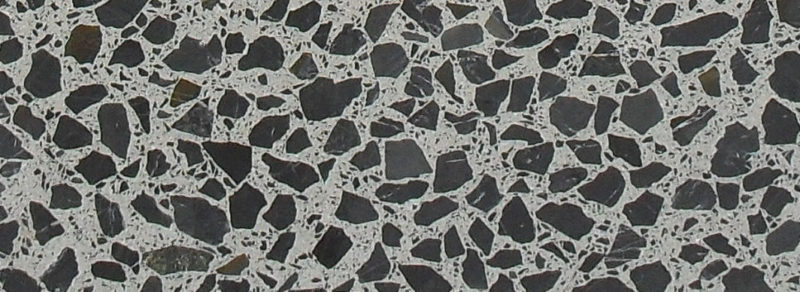

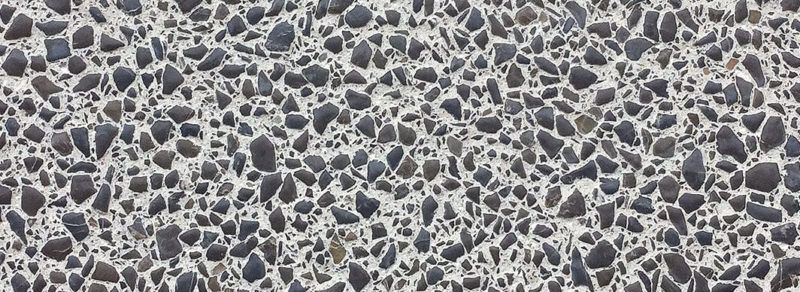

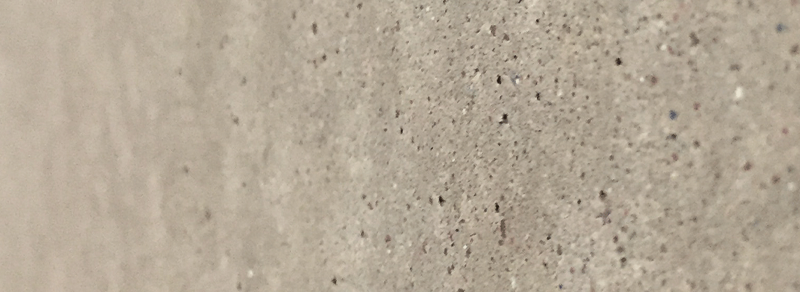

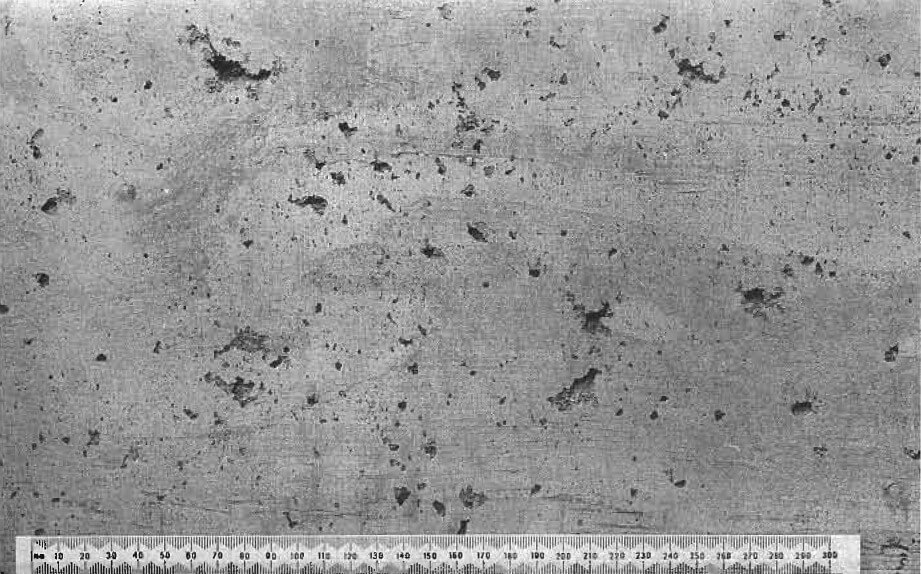

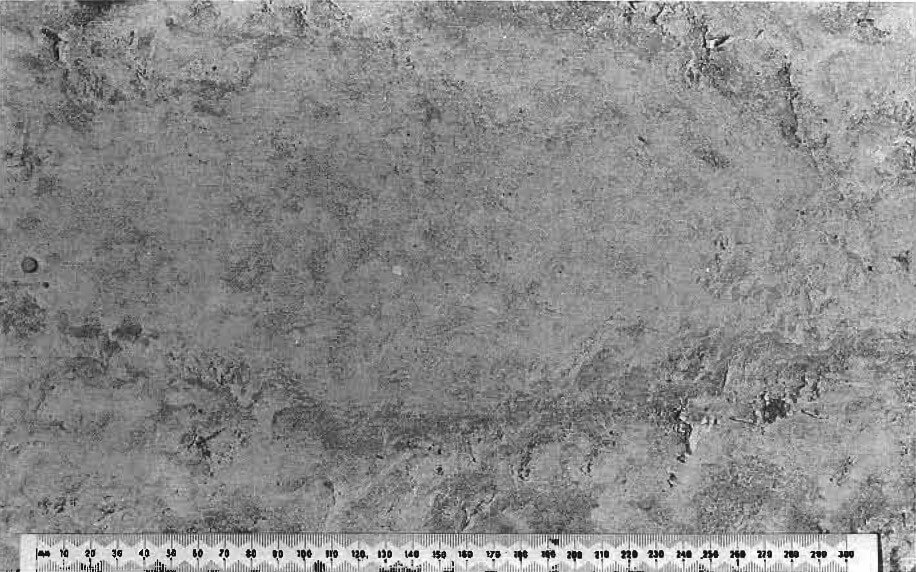

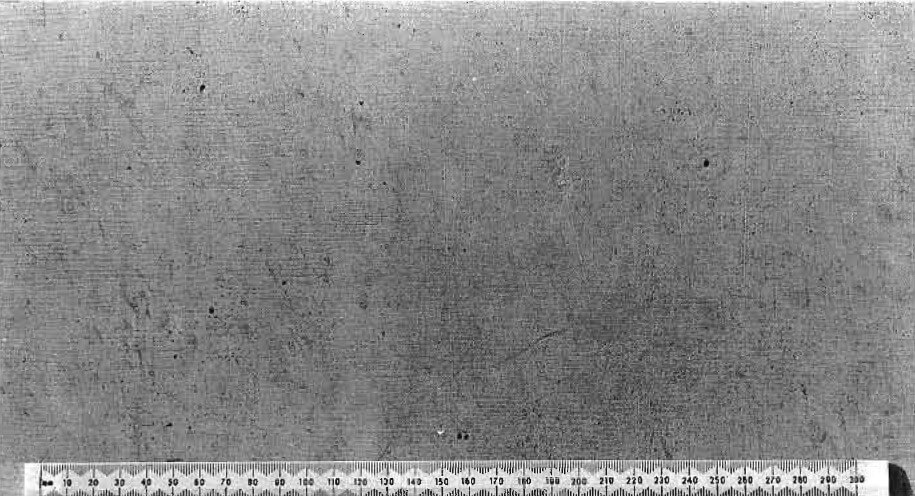

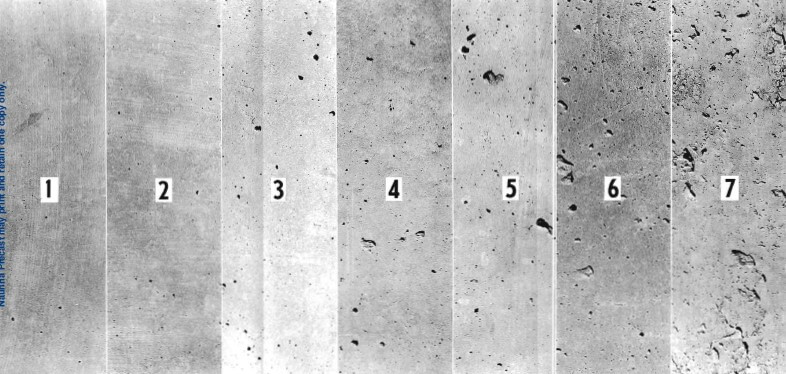

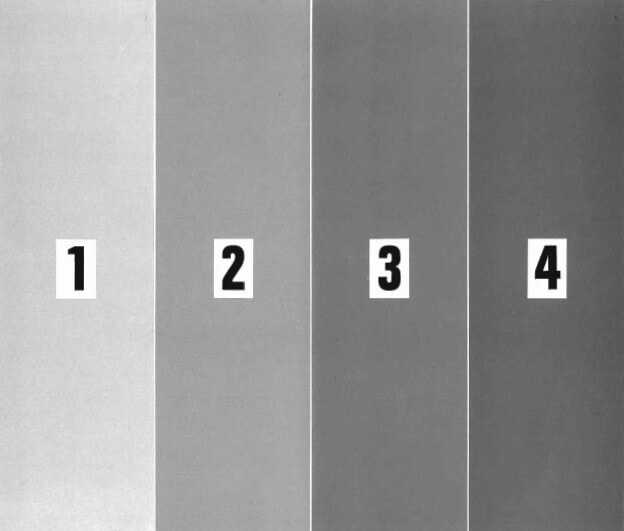

Surface Texturing:

- Diamond Honing 3650 mm

- Diamond Brushing 3650 mm

- Bush Hammering 3200 mm

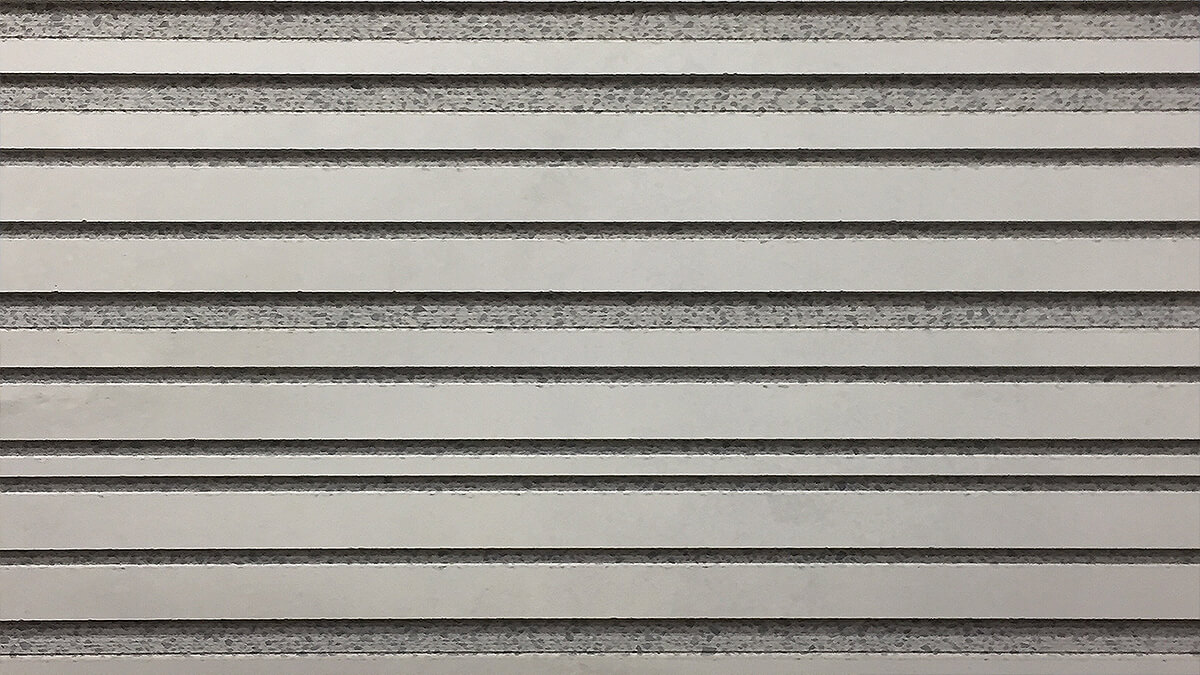

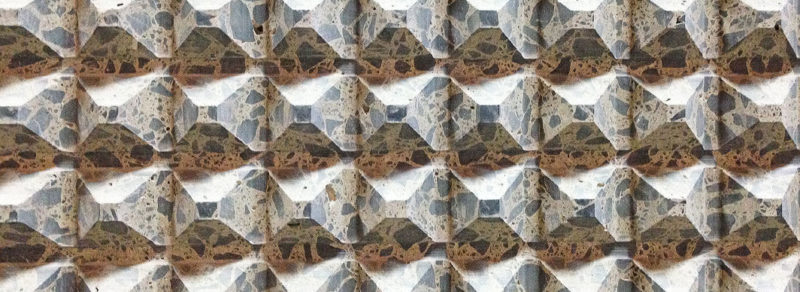

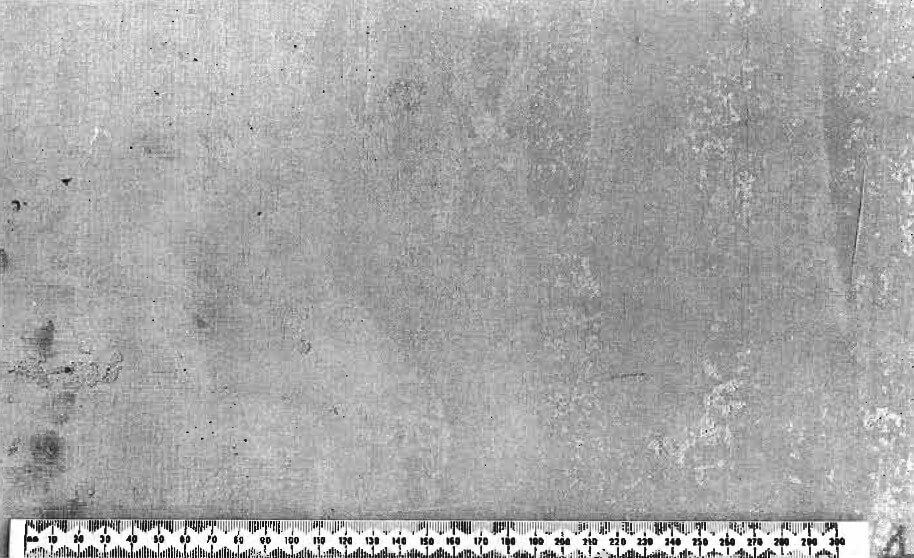

Decorative Detailing:

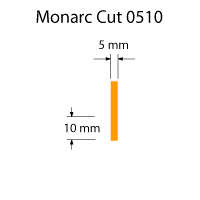

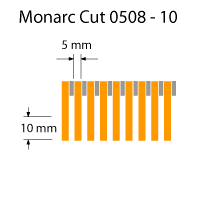

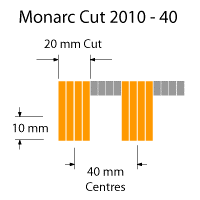

- Monarc Cutting 3200 mm

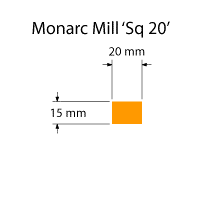

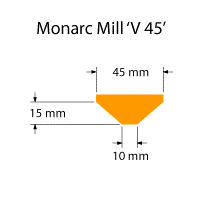

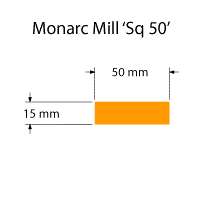

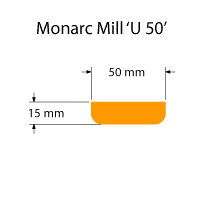

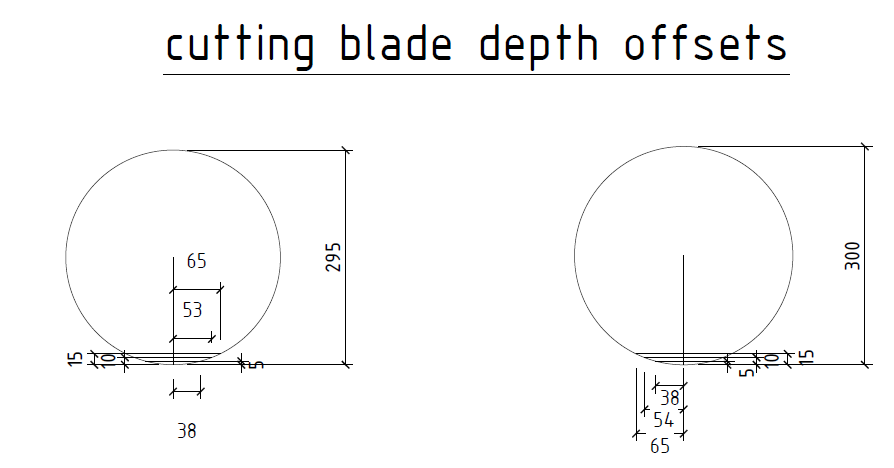

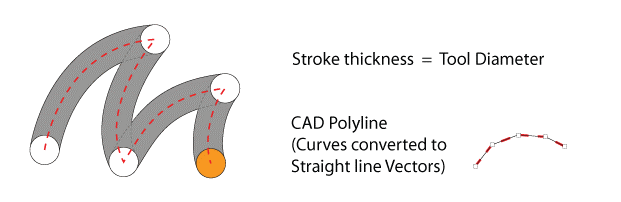

- Monarc Milling 3200 mm | 15mm depth

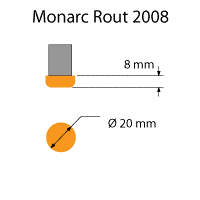

- Monarc Routing 3200 mm | 10mm depth