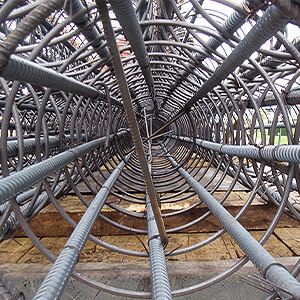

Pile Cages

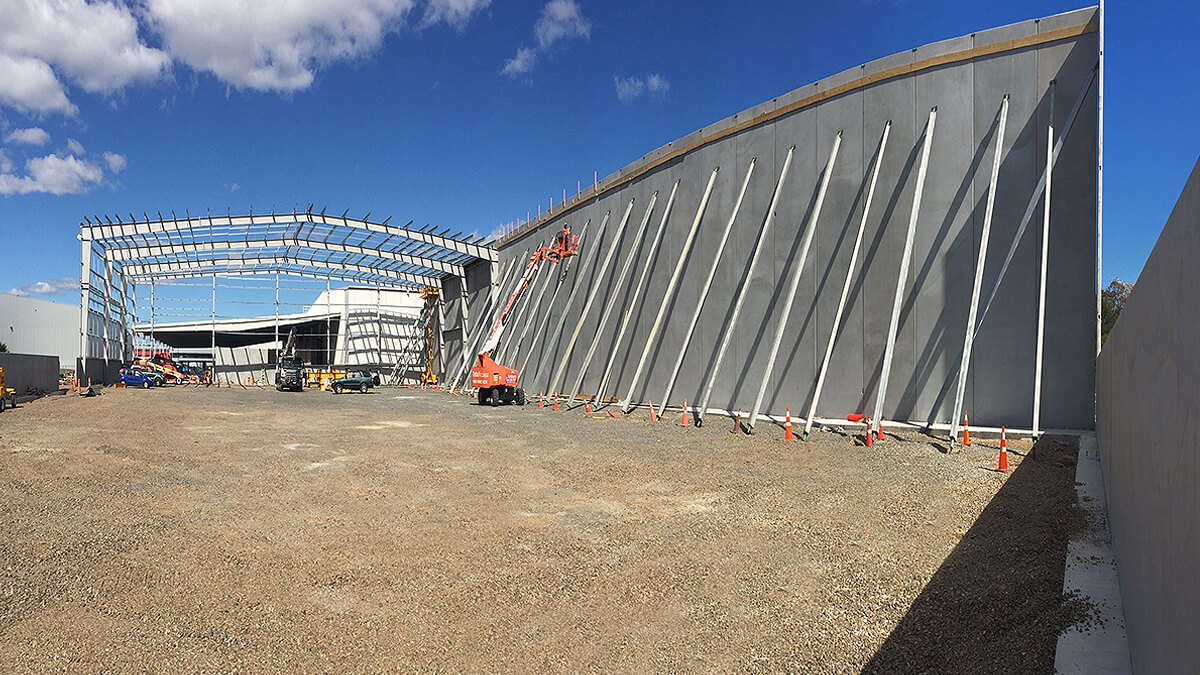

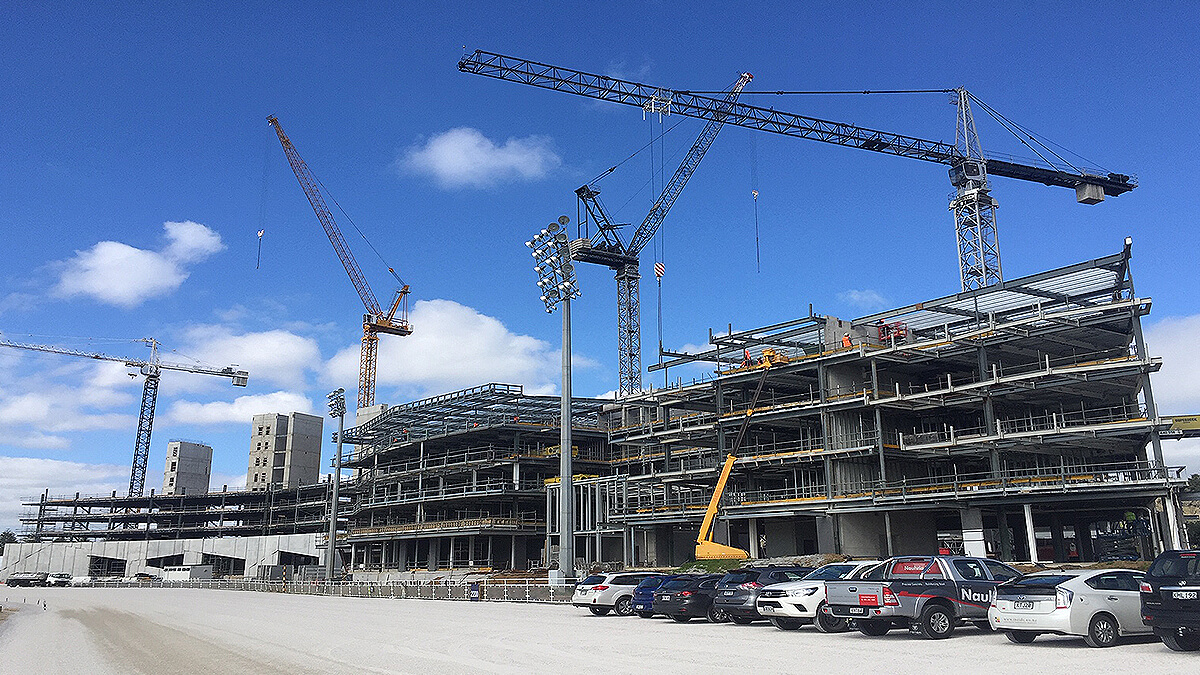

Related Projects

Engineered Purpose

Building piles underpin the foundations of a structure afixing to subterrain rock or solid matrix, to support calculated weight loads and to retain earth from general or seismic movement and collapse.

Once the pile cavity has been bored, reinforcing steel cages are lowered into the hole with spacer wheels maintaining clearance from the bored hole edges. The pile is then infilled with concrete and left to cure before pile caps and strucures are tied into the pile head section.

Details are project specific and are provided by the project engineer generally following geotechnic investigations and calculations.

Nauhria have modern production technology and wealth of experience in manufacturing Pile Cage Rebar components. Many Pile cages are often prefabricated in Nauhria’s factory prior to delivery. Prefabrication provides a number of benefits including reducing onsite delays that can reduce the risk of bored hole collapse or hole flooding and significant savings in onsite space and labour.

Lapping

As pile depths vary, it is standard practice for cages to require straight bars and spirals to be lapped onsite prior to installation. Lappage can also be required subject to pile bar design where leg end on straight bars consume straight bar length.

When lapping Spirals the engineer must instruct as to whether lap welds are permitted and or the number of Coils to provide for safe lappage.

Overlapping length of straight bars is determined by the straight Bar diameter to comply with New Zealand Standards.Top Starter bars will also require lappage.

NOTE: Welding of rebar is only permitted with written permission and instruction of the project Engineer.