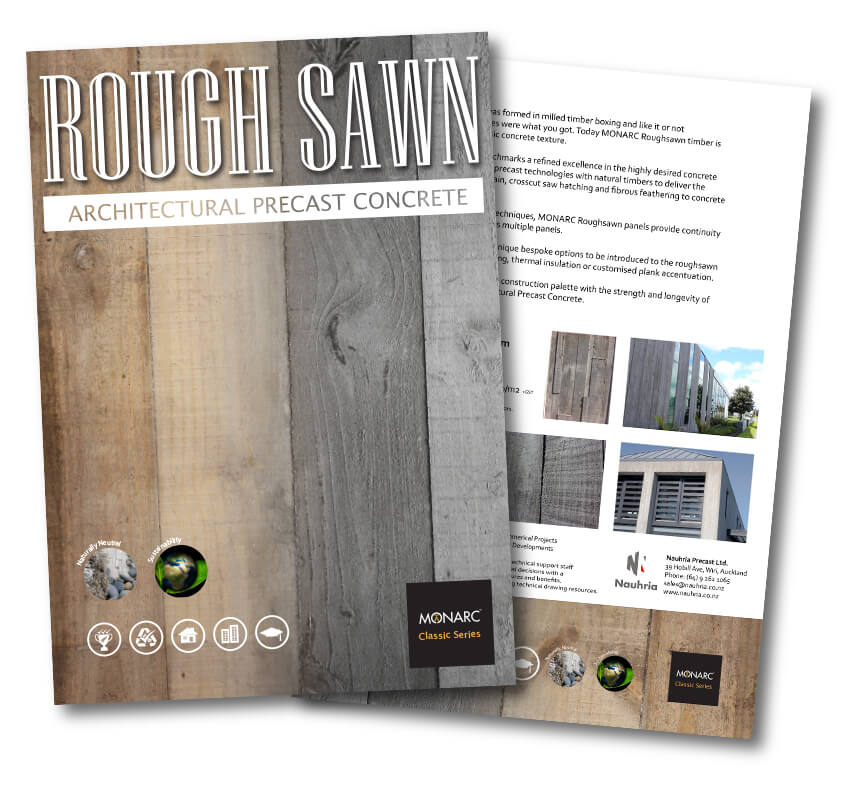

Roughsawn Timber

Related Projects

A Timeless Classic

The legacy of Rough Sawn timber goes back to times of early concrete construction where roughsawn timber was standard and used for in-situ boxing. Back then, the finish was what you got – like it or not.

As modern technologies evolved, dressed timbers, laminate boards and purpose developed formwork saw the costs and finishes of concrete make a dynamic shift towards tighter tolerances, and refined smoother concrete surfaces.

Today, Architects & Designers specify Roughsawn to deliver a natural softer aesthetic texture to building surfaces while retaining the advantages of concrete including structural and insulative properties, longevity and durability.

Today’s Rough-sawn has become become an artform and a refined skill for which Nauhria are well experienced.

Options

Plank widths can be milled to any size but for economy and savings standard sizes available include:

- 150 mm

- 200 mm

- 250 mm (subject to availability)

Through a process of Research, Testing and Development, Nauhria have selected Roughsawn boards from a reliable and stable supply source to ensure appearance continuity throughout a project.

Nauhria’s Rough-sawn Radiata Pine provides a cost effective genuine appearance balancing crosscut sawing with natural timber grain and knots.

Maximum plank lengths are +/- 6.0 meters with Planks placed as designed with random offset ends to provide a continuity of shuttering appearance.

Plank widths can be specified as uniform widths or at specified assortments of different widths.

As the weight of concrete flattens the feathering of the timber planks following casting, feathering can be refreshed a few times before the timber fibres become to weak to hold their roughened texture. At this point the rough-sawn timber needs to be replaced to ensure the continuity of the textures appearance over spans of wall.

Design Consideration:

Rough sawn timber will have significant concrete feathering formed from the natural Timber fibres, This highly textured surface can absorb Dust and moisture creating ideal conditions for green organic growth on the surface overtime.

Specifiers should also consider the abrasive attributes that partner Roughsawn timber, Entryways and areas with close pedestrian exposure could cause snagging or skin abrasion if contact is made.

In these situations we suggest consider non abrasive finishes like Monarc’s beautifully tactile Diamond Brushed architectural finish.