3D Moulded Forms

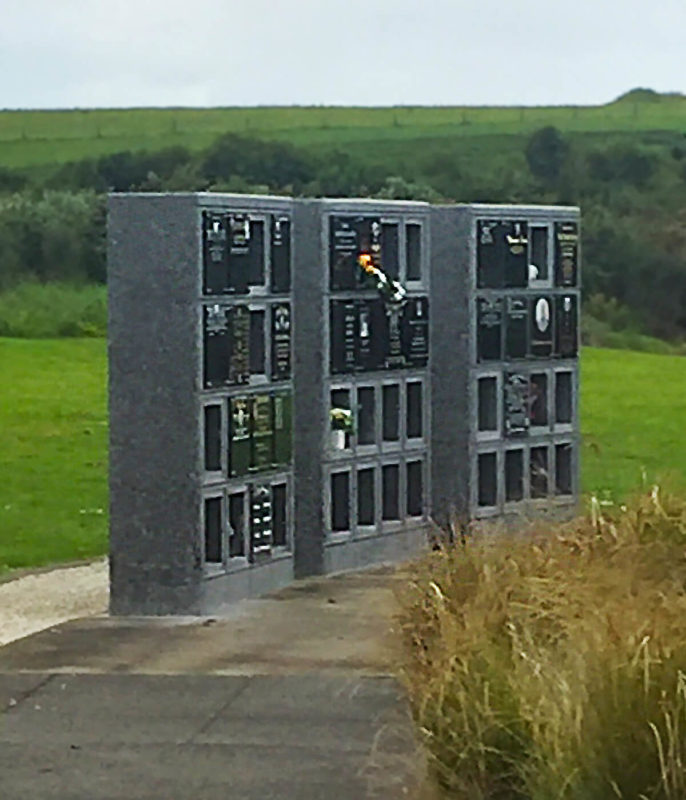

Related Projects

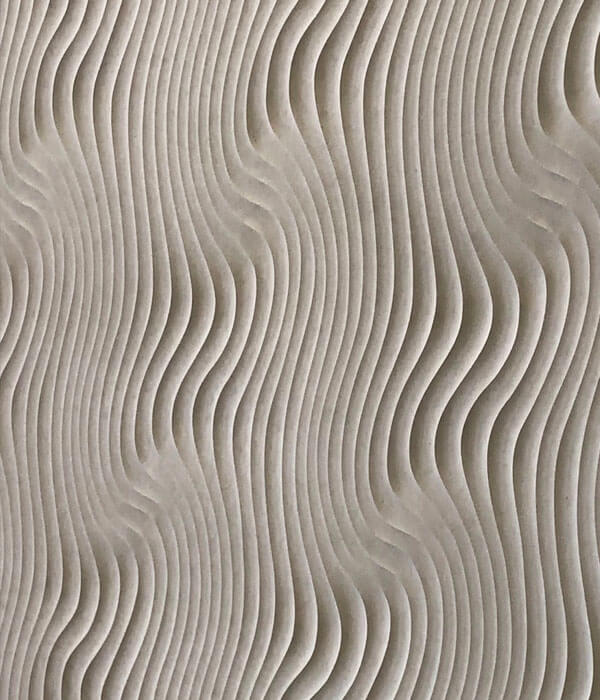

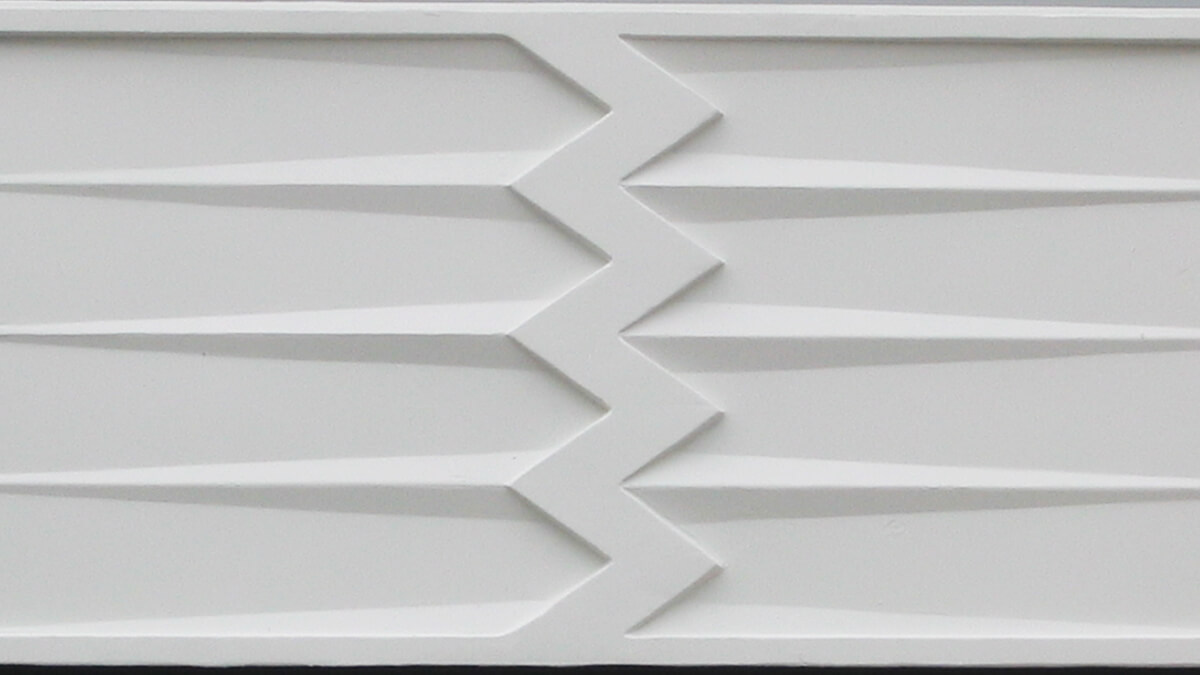

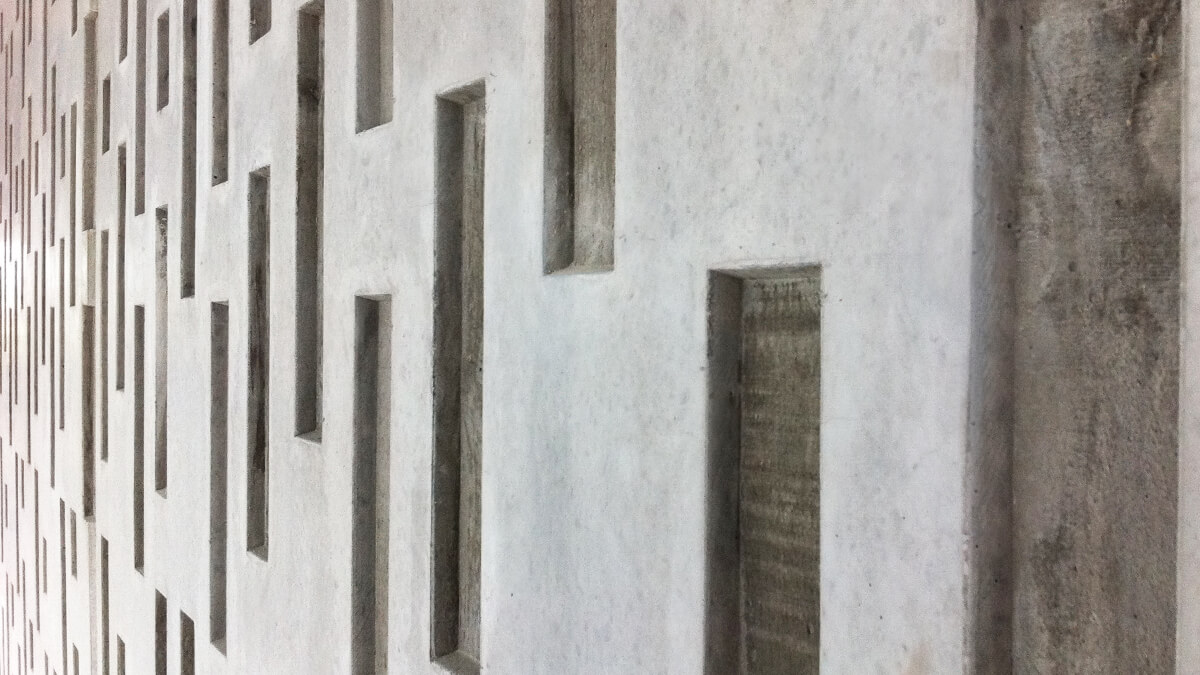

Form-liners

Concrete is an amazing product capable of transforming from a blended liquid state to solid in any cast shape or 3 dimensional form.

Selecting the form can be as simple as making a selection from global form-liner catalogs or as bespoke as designing a project specific design.

Mould Cost Considerations

When castings multiple units from the form-work, upfront mould costs are amortized and distributed over the number of units and can be very cost effective to the project.

Upfront costs can vary significantly due to many variables including:

- The number of times a form-liner is required to be used – This determines the best material to manufacture the form from.

- The profiles within the form itself, Positive or negative release forms

- The material the mould form is made from.

- Location and Logistics (eg. Germany, USA, Australia or local)

Mould Materials

Mould form materials are determined by the number of castings and the release-ability of the form. The more common materials for moulds include:

- Wood / Laminates

- Plastic / PVC

- Metal

- Fibre-glass

- Rubber

- Concrete

Design Considerations

If your thinking of using a mould for your precast there are a few additional aspects that should be considered these include:

- Pattern continuity or framing of pattern over large areas.

- Ongoing cleaning and maintenance requirements and accessibility.

- interaction of the cast surface with people and the environment.

- The effect that play of light can make on the form during daylight and through artificial illumination.